The internal combustion engine

Internal combustion engine is a fluid machine applicable as a heat engine. All heat engines of static pressure arrangements, it is necessary to provide a working vessel- the volume of which is capable of variation, work being done on a moving portion of walls (known as pistons) by the static pressure of working fluid as its volume increases. In both the pressure and temperature fall with the increase of the working chamber. The first engine which was operated with lighting gas was constructed by N.Otto in 1878. Rudolf Diesel has designed a new type of high-compression engine which was constructed in 1897.

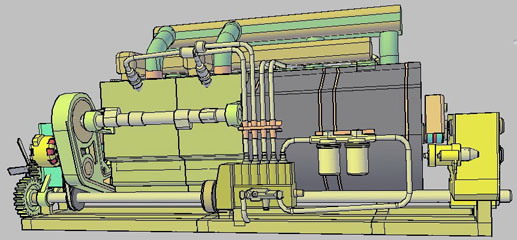

To day in most applications of power generation and in transportation propulsion the power source have being the internal combustion engine. Cars, trucks, off-highway vehicles, railroad, marine, motor bikes - as well as mechanical and electrical power generators for a wide range of large and small applications. Vital parts of the IC engine are the cylinders, pistons and crank gear. The form of the working chamber is a straight cylinder with movable piston in it. Therefore the motion of the piston is in a straight line, whereas in the majority of applications the final motion required is a rotary one. So that,the straight line motion generated in the engine is converted in to continues rotary motion using crank gear and delivered to consumer.

An internal combustion engine is operated in two main cycles. They are two stroke cycle (Clerk cycle) and four stroke cycle(Otto cycle). To complete a single sequence of operation (i.e. cycle), the mobile portion or the piston has to perform number of stokes. This cycle or the sequence has to take place continuously as long as the engine works.

Engine efficiency

In most machines, including engines some part of work done is expended in over coming friction or resistance of that nature; and the remaining portion is described as useful work. The ratio of useful work to the whole work done is called the efficiency of the machine.

The degree of heat utilization in internal combustion engines is determined by different efficiencies: thermal, overall, mechanical, etc.

The thermal efficiency of the working cycle of an engine characterizes the degree of perfection with which heat is converted in to work, without account taken of losses involved in friction, cooling, heat transfer, etc. This cycle accounts only for the heat lost with the exhaust gases.

Four stroke cycle-The Otto Cycle

Each movement of the cylinder up or down the cylinder is a stroke. The most widely adopted combustion process is four stroke cycle, for its higher thermal efficiency and greater economy.

The four stroke cycle consists of an induction stroke where air and fuel are taken into the working vessel as the piston moves downwards, a compression stroke where the air and fuel are compressed by the upstroke of the cylinder, the ignition or power stroke where the compressed mixture is ignited and the expansion forces the cylinder downwards, and an exhaust stroke where the waste gases are forced out of the cylinder. The intake and outlet ports open and close to allow air to be drawn into the cylinder and exhaust gases to be expelled. Most modern internal combustion engines use the four stroke cycle.of the four stroke combustion cycle or Otto cycle.

Two-stroke engine

Two-stroke engines do not have valves. Simple in construction.It generate a power pulse in each revolution of the crank gear. So that it's having a higher power to weight ratio.

During the working cycle, the crankshaft starts driving the piston toward the spark plug for the compression stroke. While the air-fuel mixture in the cylinder is compressed, a vacuum is created in the crankcase. The crankcase, is creating a vacuum to suck in air/fuel from the carburetor through the reed valve and then pressurizing the crankcase so that air/fuel is forced into the combustion chamber from the carburetor. Once the piston leads to the end of the compression stroke, the spark plug fires to generate combustion pressure to drive the piston. The sides of the piston are acting like valves, covering and uncovering the intake and exhaust ports communicating into the side of the cylinder wall.

Two stroke engines lighter, simpler and less expensive to manufacture.They have a greater power to weight ratio.But they are lesser in efficiency and it require lubrication oil to be fed with fuel.